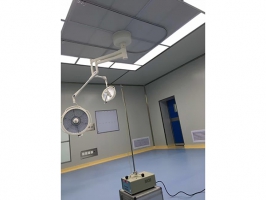

Design points of Guangdong clean and dust-free workshop project

1、 To meet the requirements of production technology for architectural design and achieve high-performance manufacturing space and facilities, it is necessary to fully consider the rational utilization of the site and meet the requirements of process production when designing the overall plan, layout, and section of industrial purification and dust-free workshops. When designing the building of a clean and dust-free workshop project, it is necessary to handle the relationship between the clean area and its related auxiliary areas.

2、 When designing a clean and dust-free workshop, it is necessary to effectively utilize the space composition used for production processes, purification air conditioning, and public power facilities to achieve economical operation, energy conservation, easy maintenance, and cost reduction. This can be achieved by saving area, reducing energy consumption, and preventing pollution or cross pollution. The architectural design of a clean and dust-free workshop must ensure cleanliness, ease of cleaning, prevention of internal and external pollution, and prevention of particle generation, retention, and accumulation.

3、 High reliability operating facilities should be used to purify the cleanroom building design, ensuring the safe operation of building equipment and ensuring the safety of personnel and property in the event of an accident. The main structure should have the same level of process equipment, building treatment, and decoration as the cleanroom, and the durability and fire resistance of the cleanroom. The decoration should be coordinated with the equipment level to ensure the long-term effectiveness of the investment.

4、 The building plan and spatial layout of the facility clean room that can adapt to future changes should be flexible, creating conditions for the adjustment of production processes. The main structure should adopt a large space and large-span column grid, and should not use an internal wall load-bearing system. This way, process and production equipment adjustments can be made without increasing the area and height.

The article originates from Guangdong Purification Engineering: http://www.jmyujie.com/

-

07-01

Guangdong Purification Engineering: What are the cleanroom construction companies?

Our cleanroom needs to go through several processes to be built. In the early stage, we need to start with the design, followed by the specific construction stage, and then the acceptance and other pr

-

12-19

A Brief Discussion on the Development Factors and Variables of Hunan Purification Engineering

Purification engineering can effectively utilize the six cost element variables mentioned below, provide selectable planning plans, improve fundamental purification engineering planning and standards,

-

11-27

How to effectively utilize the air conditioning system in the purification workshop of Hunan Purification Engineering Analysis

The energy consumption of HVAC system accounts for about 60% of building energy consumption, so energy conservation of HVAC is particularly important in building energy conservation. The purification

-

11-20

How to Reasonably Control and Mediate the Cost of Hunan Purification Engineering Analysis

When planning the manufacturing of purification engineering, how to achieve maximum benefits with minimal investment and complete maximum output has always been a highly valued issue for purification