What is the standard for a 100000 level purification workshop

Do you know what the specifications for a 100000 level purification workshop are?

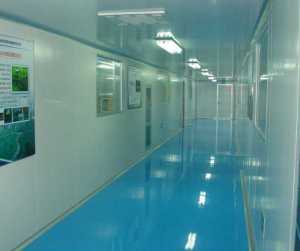

We have seen 100000 level purification workshops in many places, and the requirements for many cleanroom grades are basically within this range. So many people want to know what the specifications for 100000 level purification workshops are? In layman's terms, a 100000 level purification workshop refers to a workshop where the particles per cubic meter are controlled within 10W. If there is a 100000 level production workshop in the food industry, it is quite good!

The 100000 level purification workshop standard can be understood as a standard for cleanliness from the perspective of industry standards. The general classification of cleanliness levels usually includes 10 levels, 100 levels, 1000 levels, 10000 levels, 100000 levels, and 300000 levels!

From the perspective of air exchange rate:

100000 (100000) level requires 18-25 air changes per hour, and the air purification time after ventilation should not exceed 40 minutes.

The 10000 level requires 25-30 air changes per hour, and the air purification time after ventilation should not exceed 30 minutes.

The 1000 (1000) level requires 40-60 air changes per hour, and the air purification time after ventilation should not exceed 20 minutes.

The cleanliness standards for various levels, including 100000 level purification workshops, are as follows:

ISO 14644 distinguishes the level of air cleanliness in cleanrooms (zones) and related controlled environments based on the sole objective of suspended particle concentration, and only considers particle populations with cumulative particle size limits (lower limits) within the range of 0.1um to 5.0um.

According to particle size, it can be distinguished into conventional particles (0.1um~5.0um), ultrafine particles (<0.1um), and macro particles (>5.0um).

Classification standards for air cleanliness: ISO14644-1 (International Standard)

The specification for a 100000 level purification workshop is:

1. Allowable number of large dust particles (per cubic meter);

2. The number of particles larger than or equal to 0.5 microns shall not exceed 3500000, and the number of particles larger than or equal to 5 microns shall not exceed 20000;

3. Large number of microorganisms allowed;

4. The number of planktonic bacteria shall not exceed 500 per cubic meter;

5. The number of sinking bacteria should not exceed 10 per culture dish.

Pressure difference: The pressure difference between purification workshops with the same cleanliness level should be consistent. For adjacent purification workshops with different cleanliness levels, the pressure difference should be ≥ 5Pa, and between purification workshops and non purification workshops, it should be ≥ 10Pa.

Article source: Hunan Purification Engineering http://www.jmyujie.com/

-

07-01

Guangdong Purification Engineering: What are the cleanroom construction companies?

Our cleanroom needs to go through several processes to be built. In the early stage, we need to start with the design, followed by the specific construction stage, and then the acceptance and other pr

-

12-19

A Brief Discussion on the Development Factors and Variables of Hunan Purification Engineering

Purification engineering can effectively utilize the six cost element variables mentioned below, provide selectable planning plans, improve fundamental purification engineering planning and standards,

-

11-27

How to effectively utilize the air conditioning system in the purification workshop of Hunan Purification Engineering Analysis

The energy consumption of HVAC system accounts for about 60% of building energy consumption, so energy conservation of HVAC is particularly important in building energy conservation. The purification

-

11-20

How to Reasonably Control and Mediate the Cost of Hunan Purification Engineering Analysis

When planning the manufacturing of purification engineering, how to achieve maximum benefits with minimal investment and complete maximum output has always been a highly valued issue for purification